Since 1974

Berotec SA , turning and CENTRELESS grinding in Moutier

News & Updates

Annual closure for the summer holidays from July 20 to August 7, 2026 inclusive.

Tailor-made solutions for the most demanding industries in Switzerland and internationally

Swiss Turning

Precision turning

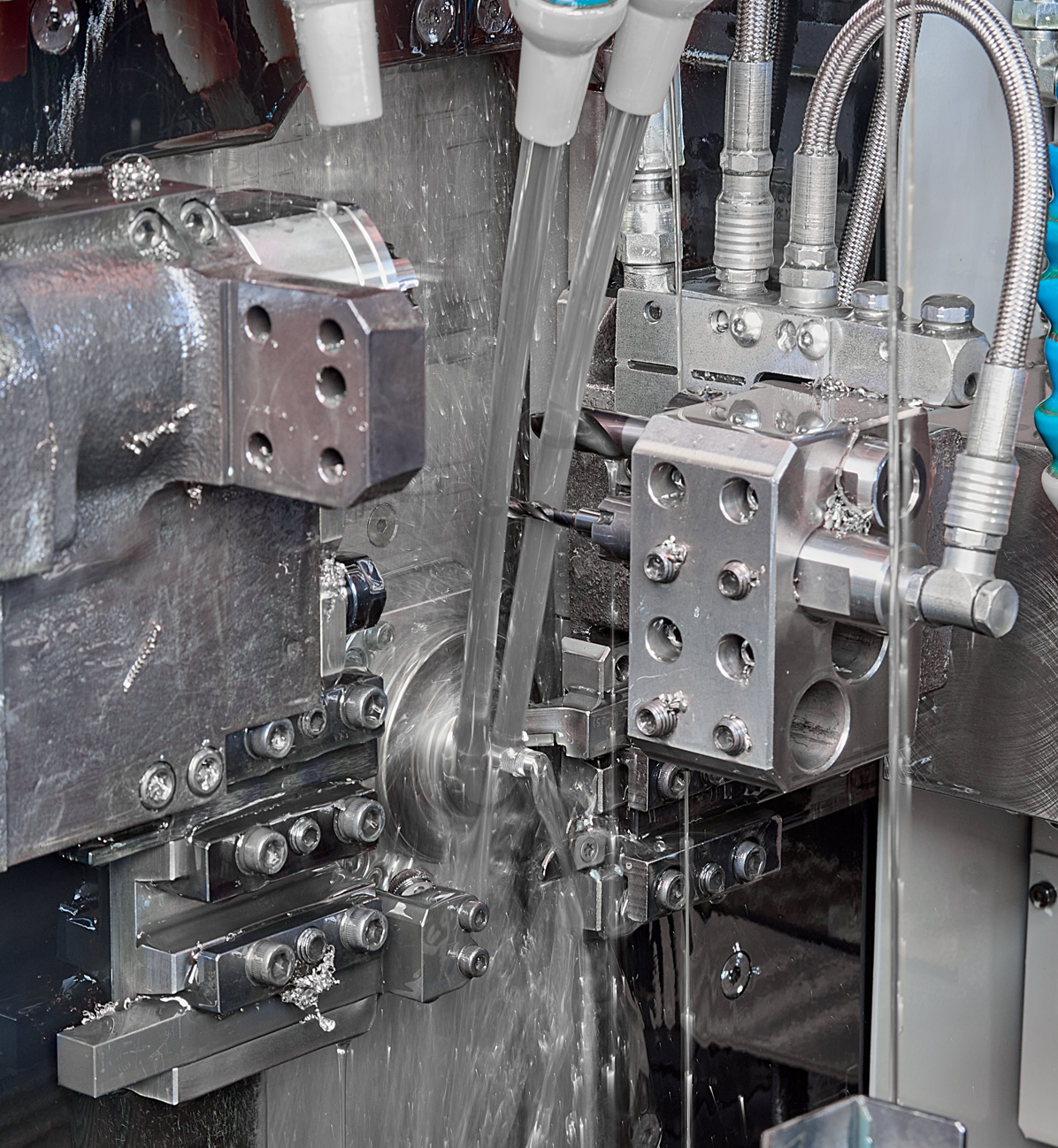

At Berotec SA, we machine complex mechanical parts in both small and large series using turning processes. Flexibility, performance and reliability: our expertise adapts to your needs, from prototype to full production. Heat treatments, surface treatments, decoration, engraving and other specific operations are handled by our network of partners, ensuring a complete and fully controlled service.

Grinding

Centreless Grinding

Our grinding workshop is equipped to guarantee flawless surface finishes and extremely tight tolerances, whether for our own production or subcontracting work. We offer bar grinding and finishing of parts produced in-house or externally, meeting the highest standards.

Who are we ?

Berotec SA – Swiss precision since 1974

For over 50 years, Berotec SA has been designing and manufacturing high-precision microtechnical components. With its broad expertise, the company has chosen not to limit itself to a single sector, convinced that each field enriches the others and drives innovation. Berotec SA supports your most ambitious micro-machining projects.

To deliver the best solutions to its clients, Berotec also relies on a network of reliable and experienced partners, enabling project industrialisation, cost optimisation and the level of quality its customers demand. We comply with RoHS and REACH standards, and, in a commitment to sustainability, our electricity consumption comes exclusively from hydropower.

As a training company, we are firmly committed to a long-term vision, investing in skills, quality and innovation.

Why choose Berotec SA?

Solutions designed for your needs

Cross-functional expertise

Our expertise adapts to the requirements of various sectors such as medical, watchmaking, metrology and aeronautics.

Close collaboration with our clients

We place listening, discussion and co-construction at the heart of each project to guarantee tailor-made solutions.

A network of reliable and specialised partners

Heat treatments, cam turning, surface finishes: we rely on a solid ecosystem to meet all your requirements.

Emergency stocks according to your needs

For greater responsiveness, we offer customised emergency stock solutions.